KOCH CENTRONIC

Cutting-, drilling and dowelinserting machine

Vebim reference: 5211

Machine number: A1104/8018

Year of construction: 2011

Tension: 400V 50Hz 3Ph

Machine designed for machining solid wood doors with frame and raised panels

Workpiece dimensions Length 150 - 3000 mm Width 40 - 300 mm Thickness 20 - 60 mm

Material: hard woods/soft woods

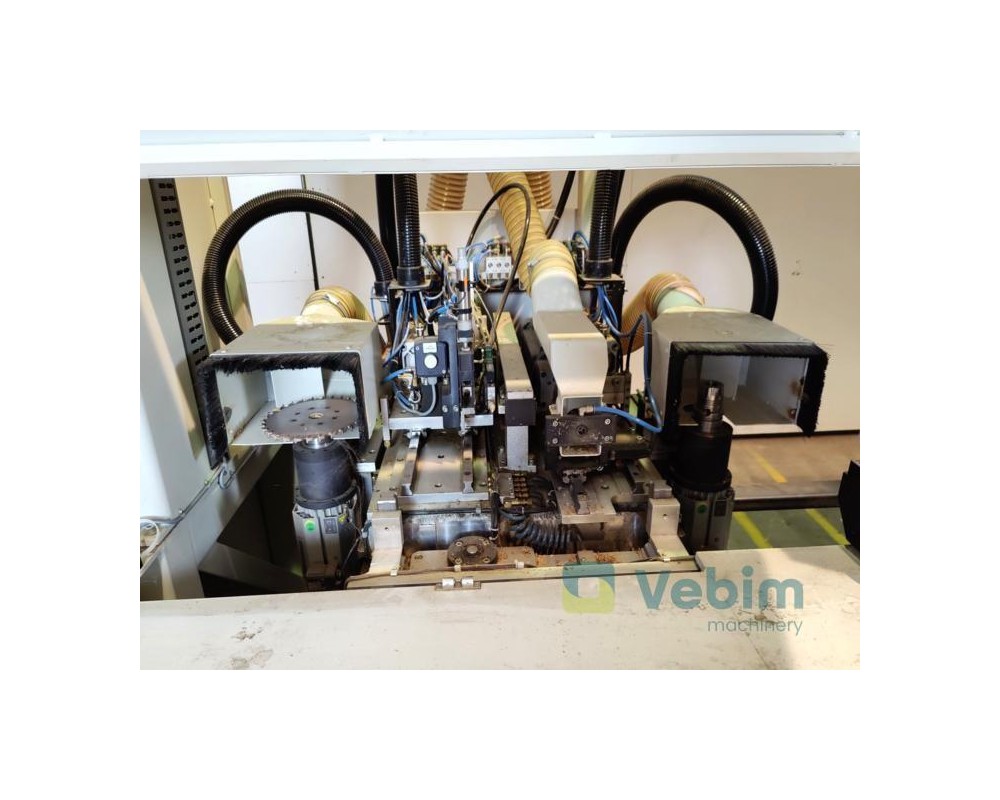

Machine equiped with 2 working areas, including

- 3 NC-axes X, Y, Z

- telephone modem

- 1 sawing unit

- 1 horizontal boring unit

- distance horizontal drill above table (Z):max. 40 mm

- fixed workpiece table

- central lubrication

- CE package

- max. workpiece length 2.400 mm

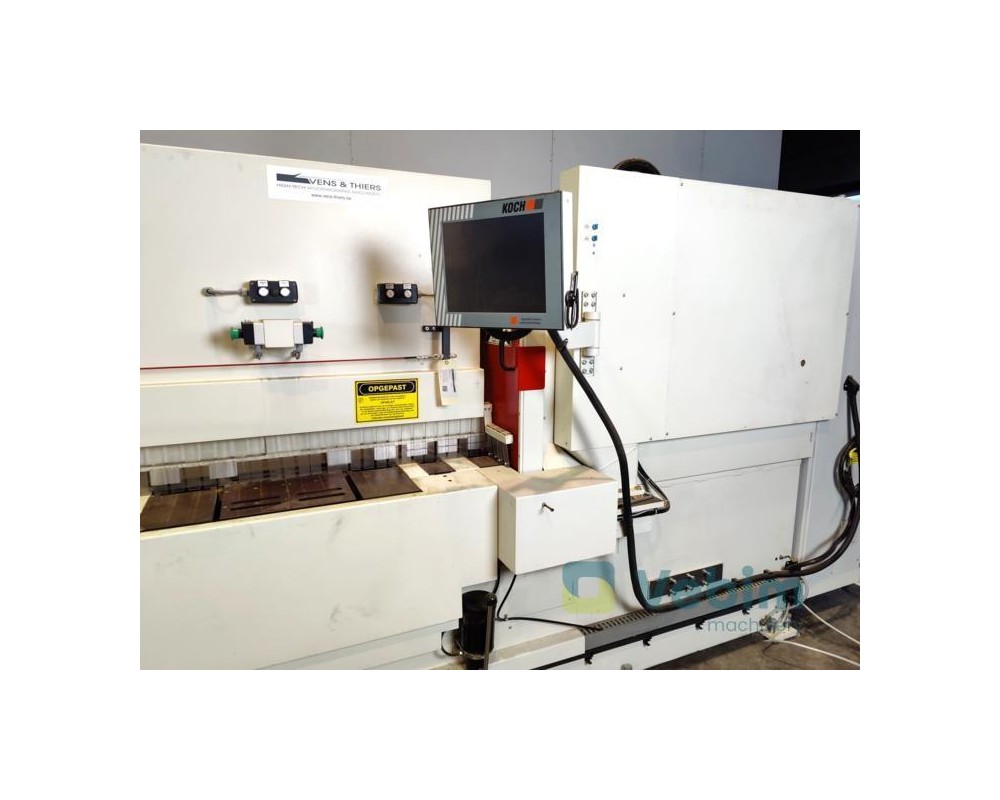

KOCH Numeric with 3 NC-axes

Positioning control with PC

Pentium CPU

Operating system Windows XP Professional: english

15” Touchpanel

VGA + Touchscreen by means of LVDS connection

USB-connection on PC and on Touchpanel

Seriel and parallel interface on the PC

Hard disk 2,5“

Input of machine commands and motor control through the Touchpanel

PS2 connection for external keyboard

Office PC software

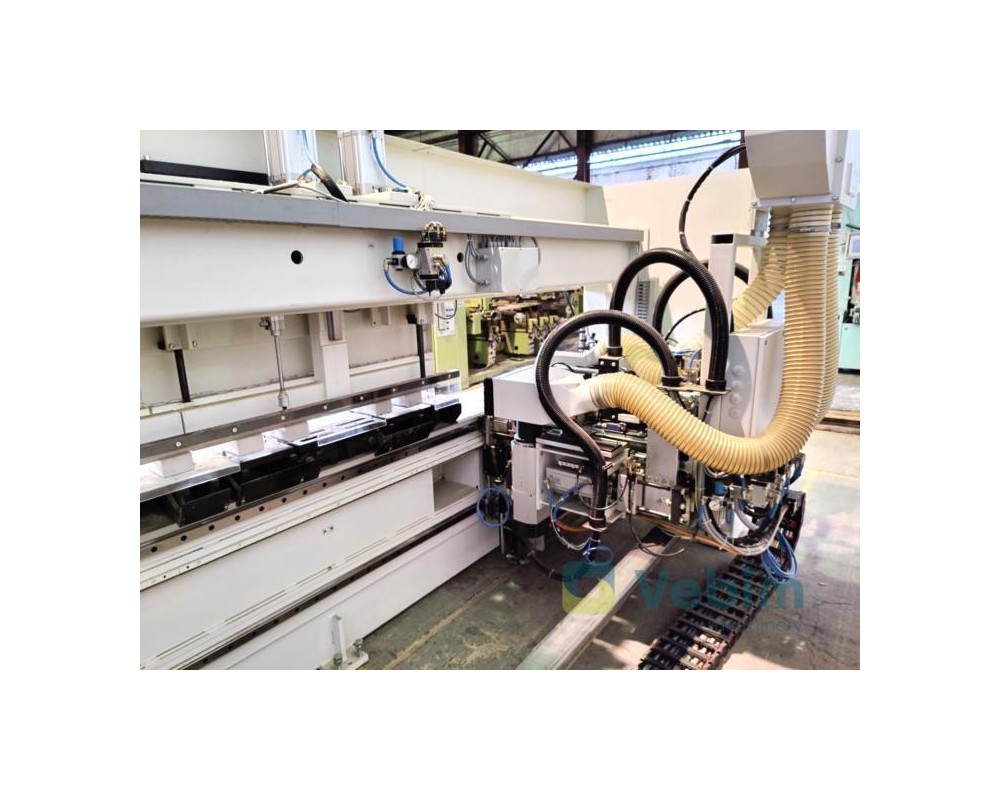

Stretched machine bas for max. workpiece width 3000 mm Workpiece clamping system for horizontal drilling.

Fixed workpiece fences 90° 2 pcs

NC-fence

Front stops Automatically receding

Sawing station 1 motor 2,8 kW 2.800 rpm

Quick change system for saw blade clamping

1 HM-saw blade 450 x 30 mm

1 motor brake

Routing unit

1 vertical routing unit 5 kW (at 12.000 rpm), HSK 63F

Frequency control 6.000 – 12.000 rpm

Tooling diameter 200 mm

1 motor brake

Second routing unit

Working CCW

Routing motor max. 9 kW, HSK 63F

Max. tooling weight 6 kg incl. tool holder (balanced G 2,5 / ISO 1940)

Pneumatic clamp for Y axis 4 pcs

Horizontal boring station 1 boring unit 2 kW, 2.800 rpm, frequency controlled drill holing cleaning with compressed air

Drilling head model D-1242 with 1 spindle

Drill guide for 12 mm drills

Frequency changer for drill head Max. 6.000 rpm

Gluing and doweling station with 1 dowel unit dowel-12 mm dowel length 80 mm dowel projection: ½ dowel length. Variable dowel projection (Y-axis)

Dowel tollerances Dowel length +/- 1 mm Dowel diameter +0,1 / -0,2 mm Step up for dowel filling

Electronic glue control ELC

Central extraction, with pneumatically controled valves

Waste transport conveyor

Barcode reader incl. software

On line connection

Barcode-Software

High pressure glue pump ratio 18:1 glue viscosity up to 7000 mPas.

Device for length wise operation (software included)

Wirerless barcode reader

Working field for alternating crosswise operation

2nd safety curtain (router heads ar not stopped whilst moving in stand by position)

Connection data

Electrical 400 V, 50 Hz, 3 ph voltage deviation max. + 6 % bis - 10 %

Compressed air 7 bar

Extraction speed min. 30 m/sec Machine number: A1104/8018 Year of construction: 2011 Tension: 400V 50Hz 3Ph

Workpiece dimensions Length 150 - 3000 mm Width 40 - 300 mm Thickness 20 - 60 mm

Material: hard woods/soft woods

Machine equiped with 2 working areas, including

- 3 NC-axes X, Y, Z

- telephone modem

- 1 sawing unit

- 1 horizontal boring unit

- distance horizontal drill above table (Z):max. 40 mm

- fixed workpiece table

- central lubrication

- CE package

- max. workpiece length 2.400 mm

KOCH Numeric with 3 NC-axes

Positioning control with PC

Pentium CPU

Operating system Windows XP Professional: english

15” Touchpanel

VGA + Touchscreen by means of LVDS connection

USB-connection on PC and on Touchpanel

Seriel and parallel interface on the PC

Hard disk 2,5“

Input of machine commands and motor control through the Touchpanel

PS2 connection for external keyboard

Office PC software

Stretched machine bas for max. workpiece width 3000 mm Workpiece clamping system for horizontal drilling.

Fixed workpiece fences 90° 2 pcs

NC-fence

Front stops Automatically receding

Sawing station 1 motor 2,8 kW 2.800 rpm

Quick change system for saw blade clamping

1 HM-saw blade 450 x 30 mm

1 motor brake

Routing unit

1 vertical routing unit 5 kW (at 12.000 rpm), HSK 63F

Frequency control 6.000 – 12.000 rpm

Tooling diameter 200 mm

1 motor brake

Second routing unit

Working CCW

Routing motor max. 9 kW, HSK 63F

Max. tooling weight 6 kg incl. tool holder (balanced G 2,5 / ISO 1940)

Pneumatic clamp for Y axis 4 pcs

Horizontal boring station 1 boring unit 2 kW, 2.800 rpm, frequency controlled drill holing cleaning with compressed air

Drilling head model D-1242 with 1 spindle

Drill guide for 12 mm drills

Frequency changer for drill head Max. 6.000 rpm

Gluing and doweling station with 1 dowel unit dowel-12 mm dowel length 80 mm dowel projection: ½ dowel length. Variable dowel projection (Y-axis)

Dowel tollerances Dowel length +/- 1 mm Dowel diameter +0,1 / -0,2 mm Step up for dowel filling

Electronic glue control ELC

Central extraction, with pneumatically controled valves

Waste transport conveyor

Barcode reader incl. software

On line connection

Barcode-Software

High pressure glue pump ratio 18:1 glue viscosity up to 7000 mPas.

Device for length wise operation (software included)

Wirerless barcode reader

Working field for alternating crosswise operation

2nd safety curtain (router heads ar not stopped whilst moving in stand by position)

Connection data

Electrical 400 V, 50 Hz, 3 ph voltage deviation max. + 6 % bis - 10 %

Compressed air 7 bar

Extraction speed min. 30 m/sec Machine number: A1104/8018 Year of construction: 2011 Tension: 400V 50Hz 3Ph

No customer reviews for the moment.