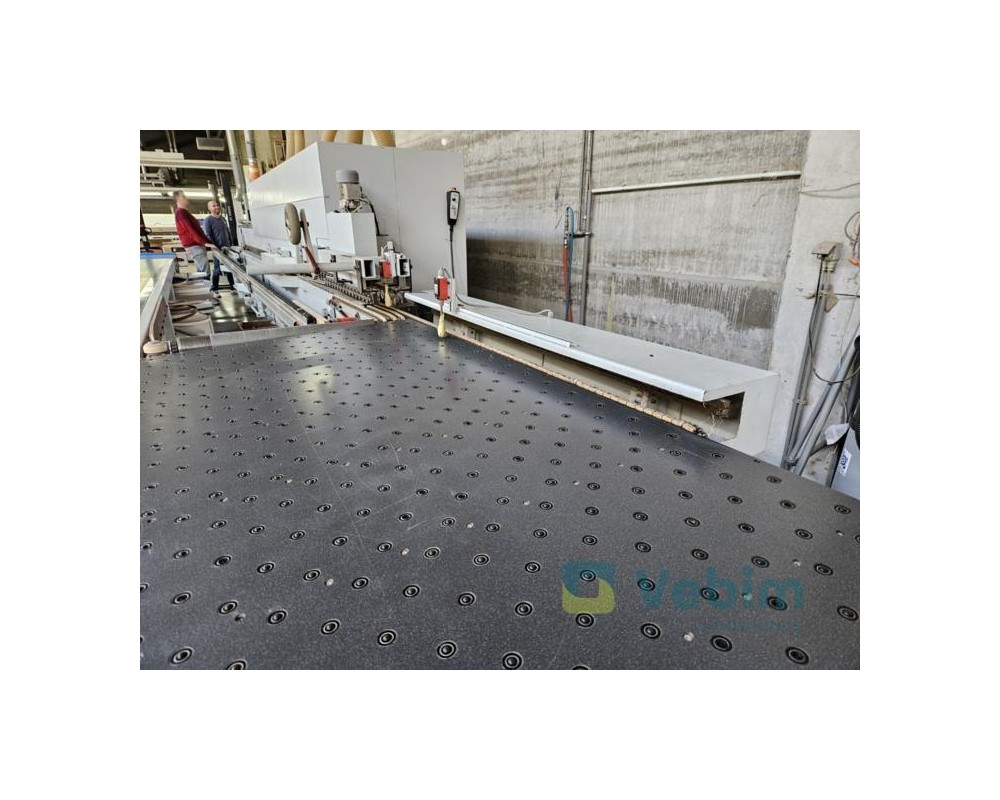

HOMAG KAL210 AMBITION 2264 - ZHR 05/L/085

Squaring and edgebanding machine single sided

Vebim reference: 5927

Machine number: 0-200-26-3219

Year of construction: 2012

Tension: 400V 50Hz 3Ph

Fixed side at the left

Feedspeed 18 - 25 m/min

Working width min 60mm for panel thickness 22mm, 105mm for panel thickness 40mm

Panel overhang 30mm

Panel thickness 8 - 60 mm in stead of 12 - 40 mm (with limitations)

Coil edge thickness: 0,3 - 3 mm, strips 0,4 - 20 mm

Coil diameter 830 mm

Equipment:

Sprayers release agent

Squaring device with 2 motors each 3 kW

Edge heating

Edge magazine for 2 coils, guillotine for edges up to 3 mm

Glueing part A20 with quickmelt application

Lateral pressure zone K, 1 driven and 6 after pressing rollers

End trims HL84, 2 motors each 0,8kW

Rough trimming, 2 motors 1,5kW

Contour trimming, 2 exchange units

Profile scraping PN10

Flat scrapers FA11

Sprayers cleaning agent

Buffing

Automation package straight/chamfer:

-Automatic adjustment infeed fence

-Automatic setting of pressure rollers

-Pneumatic setting of end trims

-Pneumatic setting of rough trims

-Automatic setting of chamfer/radius on the contour trims

-Pneumatic setting of profile and flat scraping units

-Electronic height positioning

ZHR 05/L/085 (construction year 2001)

Return conveyor for panels coming out of a single sided shaping or edge banding machine with fence at the left and with a length of approx. 8,5 m.

Max. panelsizes: 2000 x 800 mm., min. 300 x 150 mm.

At the machine outfeed, a tilting air flotation table brings the panels on the return conveyor belt

Long panels pass a fence roller which turns them lengthwise on the return belt Machine number: 0-200-26-3219 Year of construction: 2012 Tension: 400V 50Hz 3Ph

Feedspeed 18 - 25 m/min

Working width min 60mm for panel thickness 22mm, 105mm for panel thickness 40mm

Panel overhang 30mm

Panel thickness 8 - 60 mm in stead of 12 - 40 mm (with limitations)

Coil edge thickness: 0,3 - 3 mm, strips 0,4 - 20 mm

Coil diameter 830 mm

Equipment:

Sprayers release agent

Squaring device with 2 motors each 3 kW

Edge heating

Edge magazine for 2 coils, guillotine for edges up to 3 mm

Glueing part A20 with quickmelt application

Lateral pressure zone K, 1 driven and 6 after pressing rollers

End trims HL84, 2 motors each 0,8kW

Rough trimming, 2 motors 1,5kW

Contour trimming, 2 exchange units

Profile scraping PN10

Flat scrapers FA11

Sprayers cleaning agent

Buffing

Automation package straight/chamfer:

-Automatic adjustment infeed fence

-Automatic setting of pressure rollers

-Pneumatic setting of end trims

-Pneumatic setting of rough trims

-Automatic setting of chamfer/radius on the contour trims

-Pneumatic setting of profile and flat scraping units

-Electronic height positioning

ZHR 05/L/085 (construction year 2001)

Return conveyor for panels coming out of a single sided shaping or edge banding machine with fence at the left and with a length of approx. 8,5 m.

Max. panelsizes: 2000 x 800 mm., min. 300 x 150 mm.

At the machine outfeed, a tilting air flotation table brings the panels on the return conveyor belt

Long panels pass a fence roller which turns them lengthwise on the return belt Machine number: 0-200-26-3219 Year of construction: 2012 Tension: 400V 50Hz 3Ph

No customer reviews for the moment.